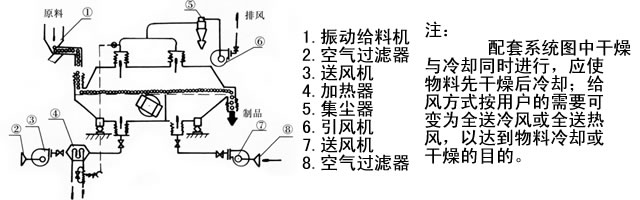

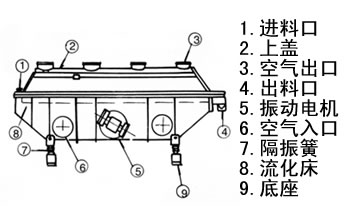

First, the working principle

The so-called fluidized bed vibration is applied to the vibration made on the basis of ordinary fluidized bed. Vibration fluidized bed dryer is exciting force generated by the vibration motor of the machine vibration, the material being processed is the role that a given direction exciting force jump forward, while at the bottom of a fluidized bed of hot air input so that the material in a fluidized state. Full contact with hot material to achieve the desired drying effect.

Second, the main technical parameters

1. Working amplitude is 0 ~ 3.2mm

2. Operating frequency deviation of ± 0.3Hz

3. Host Noise: When the fluidized bed distributor plate, is less than or equal to 2.7m2, the noise is not greater than 80dB, more than 2.7m2, the noise is not greater than 85dB

4. Motor surface temperature: When the host idling four hours, no higher than 60 ℃

5. The dry strength: When to a particle size of 1.6 ~ 3.5mm quartz sand, when under specified test conditions, dry strength of not less than 40kgH2O / hm2

Three characteristics

△ liquefied uniform and stable, no death bed and broken phenomenon can obtain uniform drying (cooling) of products.

△ vibration source of the vibration motor, smooth operation, easy maintenance, low noise and long equipment life.

△ adjustable resistance, material thickness, and material changes in the machine travel time and amplitude of the machine can achieve stepless adjustment within the design range.

△ wide adaptation of different specific gravity, particle size, moisture content, water content in the form of material can apply.

△ little damage on the surface of the material can be used for drying fragile materials, material particles irregular not affect work results.

△ working environment is clean, continuous operation.

△ heating direct heating, high thermal efficiency, energy-saving effect, saving 30% to 60% higher than the general drying device

| Model GZQ | 3×30 | 3×45 | 6×45 |

| Machine Dimensions(mm) | 3505×890×1828 | 5005×1116×1828 | 5005×1316×1939 |

| Fluidized Bed Size(mm) | 3000×272×150 | 4500×272×150 | 4500×558×150 |

| Weight(kg) | 1240 | 1570 | 1960 |

| Model GZQ | 6×60 | 9×60 | |

| Machine Dimensions(mm) | 6510×1452×1950 | 6510×2000×2120 | |

| Fluidized Bed Size(mm) | 6000×558×150 | 6000×864×150 | |

| Weight(kg) | 2744 | 3360 |

| Model GZR | 9×75 | 12×75 | 15×75 |

| Machine Dimensions(mm) | 8020×2100×2160 | 8020×2400×2742 | 8120×2636×2940 |

| Fluidized Bed Size(mm) | 7485×864×150 | 7485×1160×150 | 7485×1458×150 |

| Weight(kg) | 4032 | 5455 | 6225 |

Fifth, use and examples

The product is new drying equipment vibration fluidized principles of design, with high efficiency, excellent performance characteristics, suitable for chemical, pharmaceutical, light and food, seeds, beverages, slag, alcohol, matches, fertilizer and other industries powder, dry granular material, cooling and other operations.

Examples of typical materials dry conditions

| Material name | Material status | Dry before the water % | Dry after the water % | 8.1 hours capacity kg/h |

| Citric acid | Grain | 5 | 0.5 | 200-2000 |

| MSG | Powdery | 5 | 0.3 | 300-1000 |

| MSG | Granule | 5 | 0.2 | 350-1500 |

| Boric acid | Granule | 5 | 0.3 | 500-5000 |

| Borax | Granule | 8 | 0.2 | 300-1600 |

| Ammonium Nitrate | Granule | 2.35 | 0.1 | 400-2000 |

| Ammonium | Granule | 3.01 | 0.28 | 800-400 |

| Ammonium chloride | Granule | 4 | 0.1 | 600-60000 |

| Oxalic acid | Granule | 6.2 | 0.1 | 500-3500 |

| Sodium Saccharin | Granule | 17 | 14.3 | 350-2000 |

| Glauber | Granule | 3.6 | 0.02 | 700-7000 |

| Cellulose | Flocculent | 35 | 3.6 | 80-400 |

| Organic fertilizer | Spherical | 10.5 | 5.5 | 500-3500 |

| Potassium permanganate | Granule | 5 | 0.1 | 500-2500 |

| Silica | Paste | 78.6 | 11.8 | 80-500 |

| Soybean meal | Flakes | 16.8 | 12.5 | 1000-12000 |

| Watercress | Flakes | 13 | 10 | 1200-8000 |

| Sesame seeds | Granular | 17.6 | 3.9 | 80-500 |

| Pouce | Flakes | 14.8 | 2.2 | 160-2000 |

| Activated Carbon | Granular | 40 | 6.8 | 120-620 |

| Tea | Strip | 11.5 | 7.4 | 300-3000 |

| Distiller's grains | Granular | 56 | 10.5 | 50-1000 |

| Fracturing sand | Granule | 10 | 0.1 | 900-4500 |

| Plastic white ball | Grain | 12 | 0.1 | 150-800 |

| Thiourea | Grain | 5 | 0.3 | 200-1000 |

| Thiourea dioxide | Grain | 5 | 0.04 | 150-1000 |

| DCP | Grain | 24 | 1 | 100-800 |

| Feed yeast | Granule | 36.26 | 10 | 450-2000 |

| Sulfate | Grain | 5 | 1 | 500-2500 |

| Matchstick | Strip | 45.6 | 8.1 | 200-1000 |