First, the working principle

The machine is designed with the principles of heat transfer and heat radiation material through feed screw into the dryer, the housing rotating bundle under agitation peripheral shovel full contact with the heat transfer tubes, so that the water was evaporated, while promoting shovel the material from the feed end to the discharge end of the conveyor. Drying generally countercurrent heating, it may also be needed downstream heating.

Main characteristics

1, the aircraft low energy consumption, high thermal efficiency;

2, the machine is good in regulation and wide range;

3, easy to install, easy to operate, easy maintenance;

4, the working environment is clean, noise.

Third, the use

It is widely used in light industry, chemical industry, food, food, feed and other industries, such as lees, beer tanks, fertilizer, corn germ, corn fiber, gluten meal, rapeseed cake, chicken manure powder, granules, flakes dried fibrous loose class without too much sticky material.

Four, JDG type mobile grain dryers parameters

| Project (model) | Host power KW | Design pressure Mpa | Design temperature ℃ | Heat consumption kg Steam/kgH2O | Working Pressure Mpa | Heat transfer area m2 | Speed r/min | Dimensions mm | Total Kg |

| JDG-40 | 7.5 | 0.65 | 170 | 1.4-1.5 | 0.6 | 40 | 10 | 7120×1526×2245 | 5870 |

| JDG-80 | 11 | 80 | 7490×2100×2730 | 10137 | |||||

| JDG-100 | 11 | 100 | 9064×2591×2706 | 12172 | |||||

| JDG-150 | 15 | 150 | 8937×2130×2378 | 13641 | |||||

| JDG-180 | 18.5 | 180 | 9728×2670×2380 | 15980 | |||||

| JDG-210 | 18.5 | 210 | 9734×2272×2642 | 17986 | |||||

| JDG-250 | 22 | 250 | 11517×2272×2462 | 21299 | |||||

| JDG-300 | 30 | 300 | 11903×2434×2848 | 22693 | |||||

| JDG-350 | 30 | 350 | 12118×2662×3104 | 28458 | |||||

| JDG-400 | 37 | 400 | 13093×2662×3253 | 30679 | |||||

| JDG-475 | 37 | 475 | 13303×2850×3233 | 34206 | |||||

| JDG-500 | 37 | 500 | 13586×2856×3233 | 35703 | |||||

| JDG-525 | 37 | 525 | 13991×2850×3233 | 36795 | |||||

| JDG-600 | 45 | 600 | 13032×3066×3508 | 43112 | |||||

| JDG-700 | 55 | 700 | 14296×3066×3508 | 47711 | |||||

| JDG-800 | 75 | 800 | 13734×3310×3740 | 53558 |

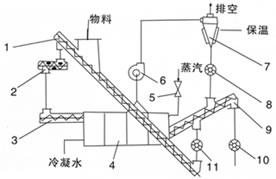

Fifth, the typical process flow diagram type

| 1. mixing screw 7. Dust 2. transport mixer 8. fan off 3. The feed screw 9. The discharge screw 10. The dryer fan off 5. Adjust the fan off valve 11. 6. Fan |  |